Robotic marking goes a step further to simplify product traceability

Danieli Telerobot, in partnership with Green Project, jointly developed the next generation in product traceability thanks to QR code marking.

Product traceability has become an integral part of quality control systems: a modern plant requires tracking production from melting down to finished products, as well as internal tracking of bars and bundles from the finishing line, through the bundle yard and, finally, external tracking until the product is delivered to the customer.

Thanks to DIGI&MET software solutions, Danieli Telerobot is able to provide production tracking from scrapyard down to the finishing line, where a label is printed out with a code identifying the required information collected along the production chain. Q-ROBOT Roll Tag provides tagging operation, affixing the printed label to the finished product.

Such operation makes the product traceable even after its shipment from the production unit, so that during transportation and until delivery to the final user every information—product ID, origin and quality classification among others—is available.

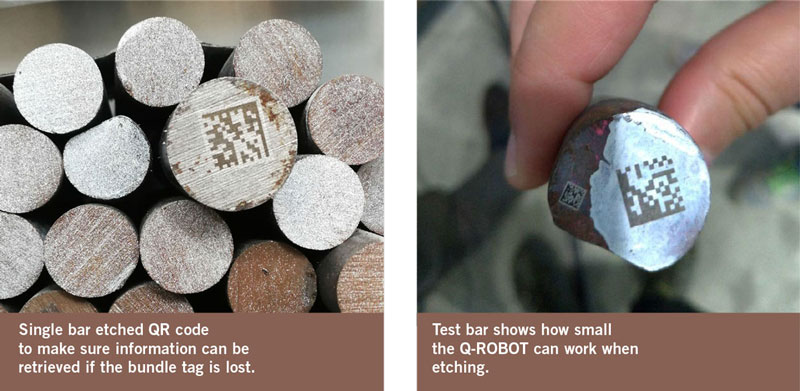

Even if tagging operation is provided in a reliable way, either welding or hooking the tag to the bundle, extreme and unpredictable conditions during transportation could cause the tag to be lost, making the product untraceable and rejected by the customer. Additionally, tags, welding-wire and pins commonly used to attach the label to the bundle represent a fixed OpEx cost for the customer. So, we set out to simplify marking operations, while making it cheaper too. Danieli Telerobot, powered by Green Project, has designed and put in operation an innovative line of Q-ROBOT Roll Marks which, thanks to a laser, etches a QR code on the head of one of the bars making up the bundle, guaranteeing a flexible and easier marking operation. Marking a QR code allows for much more information to be transferred compared to what usually can be printed on a label.

Such application—already installed and in operation—provides the following main benefits: reduced OpEx for the customer (no need for accessories used in traditional labelling), which ensures a faster ROI; easy automatic reading at the customer’s warehouse thanks to a QR code reading system and use of traditional smartphones and/or smart glasses; no risk of losing tags during transportation nor risk of returned products from final user due to missing tags.